Suitable for factory halls and exhibition buildings.

Industries are subject to strict ventilation rules based on the number of people and activities on the workfloor.

In practice, ventilation systems extract hot air from the premises in winter. In hot summers, they extract cool air and replace it by hot outside ventilation air. Neither of these situations benefit the climate, nor people's or animals' health. Heating and cooling are necessary in order to achieve optimum climate conditions. And this, in turn, goes hand in hand with high electricity consumption and correspondingly high costs.

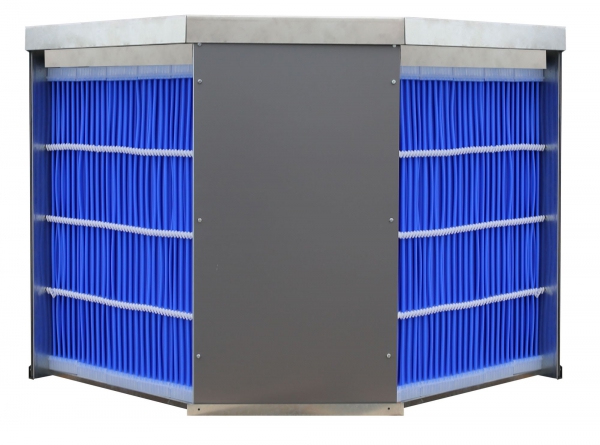

The AeroX air-to-water heat exchanger can significantly reduce energy consumption by using a split-coil configuration. One AeroX heat exchanger is placed in the outgoing air flow and another one in the incoming air flow of the premises. There is a closed water circuit between the two AeroX heat exchangers.

The outgoing air flow is fed through the first heat exchanger and transfers cold or heat to the water flowing through the tube package of the heat exchanger. This water is supplied to the heat exchanger to heat or cool the incoming air.

If this is not sufficient to achieve the temperature required, the temperature can be controlled to the correct value using conventional means.

The calculation example below shows how the Exegy AeroCalc tool can be used to give a quick indication of the payback time.

Amount of air to be changed on a cold winter's day: 50000 m³/H

Current outside temperature: -7 °C

Current outdoor RH: 90 %

Current temperature in the animal house: 28 °C

Current RH in the animal house: 70 %

The residual heat recovered from the outgoing air can be used to preheat outdoor air of -7 °C by more than 11 °C using a split-coil AeroX configuration. This energy would normally be ventilated out of the building.

Based on the energy savings achieved during one year, the payback time will be between four and six years. If production stops during hot periods can be avoided, the payback time could even be shorter than one year. Furthermore, the climate in the hall will be more stable. The higher ventilation air temperature enables ventilation to be increased while using the same amount of energy.