Suitable for factory halls and exhibition buildings.

Industrial entrepreneurs are subject to strict ventilation rules based on the number of people and activities on the workfloor. In practice, ventilation systems extract hot air from the premises in winter. In summer, they extract cool air, and replace it by hot outside ventilation air. Neither of these situations benefits the climate, nor people's health. Heating and cooling are necessary in order to achieve optimum climate conditions. And this, in turn, goes hand in hand with high energy consumption and high costs. The AeroX air-to-water heat exchanger can pre-condition the air using groundwater, thus ensuring a more constant ventilation air temperature and requiring less heating or cooling. The result: energy consumption will decrease significantly.

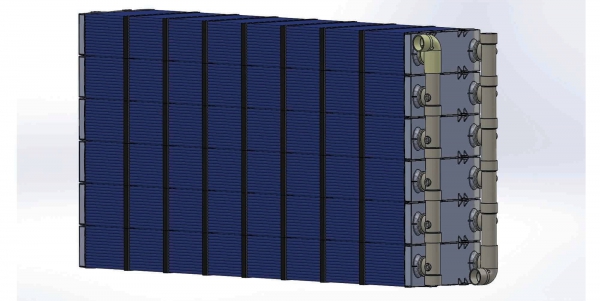

The AeroX tube package draws outside air into the building. Water that has assumed the temperature of the groundwater flows through these tubes. The groundwater temperature is fairly constant throughout the year. In many locations in the Netherlands, the average temperature of the groundwater is between 10 and 15 °C, causing the air in the tubing to heat up in the winter and to cool down in summer. A positive side effect is that - depending on the current relative humidity - condensation will form on the heat exchanger. This will make the air in the hall somewhat drier, which both humans and animals find more comfortable.

The calculation example below shows how the ExegyAeroCalc tool can be used to give a quick indication of the payback time.

Amount of air to be changed on a hot summer's day: 50000 m³/h

Current outside temperature: 30°C

Current outdoor RH: 70 %

Heat exchanger supply water temperature: 14 °C

In this situation, the air can be cooled from 30°C to 23°C. This will also create condensation on the tube package, allowing drier air to enter the hall.

Assuming this to be the daily situation for one year, and according to the Exegy AeroCalc calculation, the payback time will be between three and five years. This payback time is based solely on the lower energy consumption. The climate in the hall will be more stable. The higher ventilation air temperature enables ventilation to be increased while using the same amount of energy.

We have had some very distinct climate changes in recent years. Temperatures of over 35°C are no longer uncommon in summer and the 40°C mark was actually exceeded in the Netherlands in the summer of 2019.

Example of a summer situation:

This can cause severe production losses in industry, especially in metalworking. Apart from the fact that high temperatures can cause health problems and can lead to reduced productivity and employee performance, precision machine tools often fail at such high temperatures.

Adiabatic cooling, i.e. cooling by evaporating water, seems to offer a good solution for this, but this form of cooling can corrode the materials being machined and the tools. So this is not an option.

Another solution is to use a chiller or a groundwater source in combination with Exegy Cube roof units to cool the incoming air. The result: a very pleasant indoor climate. A chiller or a groundwater source provides cool water to cool the air to comfortable values through the AeroX heat exchangers in the roof units. In addition, condensation in the exchanger will cause the air to become drier. The result: an even more comfortable climate.

Example of a winter situation:

The same roof units can be put to efficient use in winter to recover heat from the outgoing air and then use this heat to warm the incoming air. This enables sufficient ventilation of most production areas without any heating being required.

The sophisticated Exegy 10 climate computer measures, monitors, and controls the process fully automatically in order to optimise the climate and minimise energy costs. Temperatures, ventilation flow, and humidity are measured and controlled automatically. The result: you are in full control of the climate.